Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 3D Microreactor for Microchemical Field

Brand: FLK&Sealmann

Place Of Origin: China

Packaging: Standard or customized

Transportation: Ocean,Land,Air,Express

Place of Origin: Ningbo,China

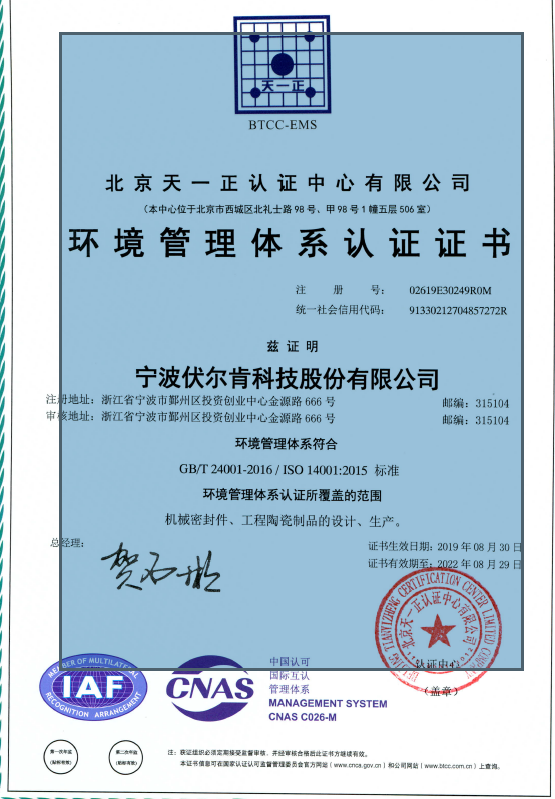

Certificate: WRAS,FDA,SGS,UKAS

Port: Ningbo,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,EXW

Product 3D Microreactor For Microchemical Field Introduction

FLK 3D printed and shaped microreactors can be used for catalytic, microreaction and heat exchange components in chemical, acid, gas, oxygen, steel, pharmaceutical and fine chemical industries to meet the needs of high efficiency, corrosion resistance, high temperature resistance, high thermal conductivity, low cost and batch size of microreactors.

Product Features

High thermal conductivity: >150W/(mK)

Can achieve more refined flow channel design and integrated structure design resistant to normal temperature acid and alkali corrosion, high temperature acid corrosion, oxidation resistance easy to manufacture complex structure resistant to high pressure vessels

3D printed Silicon Carbide ceramics

●Complex structure with ultra-lightweight, topology design

●Short production cycle and fast delivery

●No need to open molds, reducing costs and high utilization of raw materials

●Large one-piece molding diameter up to 235m

FAQ

What is the range of your 3D printing applications?

Our 3D printing products are applied in Mining And Powder, Photovoltaic Field, Semiconductor Field, Micro chemical Field and Energy & Power Field.

Why choose you as our 3D Printing Ceramics supplier?

We established since 1998,over 20 years professional experience in Advanced Materials.

Customized production according to your drawing or specification.

Strictly focus on the 3D Small Modular Reactor Microchemical Field quality .

We guarantee all direct users of all-around support, including technical consulting, solutions and product upgrading.

We always stick to the 24-hour service commitment, to maximize customer service.

Customer with strategic agreement and authorization can check inventory, order progress online at anytime.

Exclusive 40million RMB product quality bond insurance in China, valid globally and further remove the user's worries.

Are you a trading company or a manufacturer?

We are 3D Microchannel Reactor for Microchemical Field manufacturer.

Do you accept 3D Small Modular Reactor Microchemical Field customized production based on our specification?

Yes,we offer customized service.If you have drawing of 3D Microstructured Reactor for Microchemical Field , please send us your 3D printing ceramics drawing. If you don’t have RBSic 3D Printing drawing, please tell us your idea, we will work out together as business partner.

What is the payment terms you accept?

T/T,L/C are acceptable.Different customer,different situation.You can contact with our Tel or email,we can discuss together.

Other products you may also be interested in:

Mining And Powder

3d Printing Ceramics

Photovoltaic Field

Semiconductor Field

Product Categories : 3D Printing Ceramics > Microchemical

Ningbo FLK Technology Co. Ltd as the high-tech enterprise has integrated R&D, manufacture, sales and service into our series of products: engineering ceramics, mechanical seals, seal auxiliary systems, encapsulated O-rings, springs etc. And we initiated drafting and making several state and industry standards.

Our products under the trademark "FLK" are widely used in the fields of petroleum, chemical industry, ship, water treatment, steel, power, paper making, food, military and aerospace etc.

Adhering to our management idea "People oriented, technological innovation and continuous improvement", we established and implemented full-procedure control and service system in line with customer requirements, and widely accepted by customers.

Technological Innovation

1.The full study and evaluation of customer's expectations and market trends is the basis of our innovation and development. This ensures that the focus of our research and development is to meet the increasing demands of our customers.

2.We invests 5% to 8% sales revenues in R&D, and we work closely with our customers and research institutions which makes our R&D possible to meet the

challenges from multiple angles.

3.We continually invests in and improves lean manufacturing , automation , environmental protection and information technology etc, which makes our products

more reliable and costs much lower for customers .

4.We continually invests in and improves the areas of manufacturing, quality control and product verification to make our products more reliable and cost-effective.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.